The plate shear is used on the uncoiling and leveling line of plates and it is a high-speed plate shear designed to match the fast speed and shearing requirements of the production line. The thick plate lines most have hydraulic high-speed shears and the thin plate line most have electric and pneumatic plate shears.

Other parts list

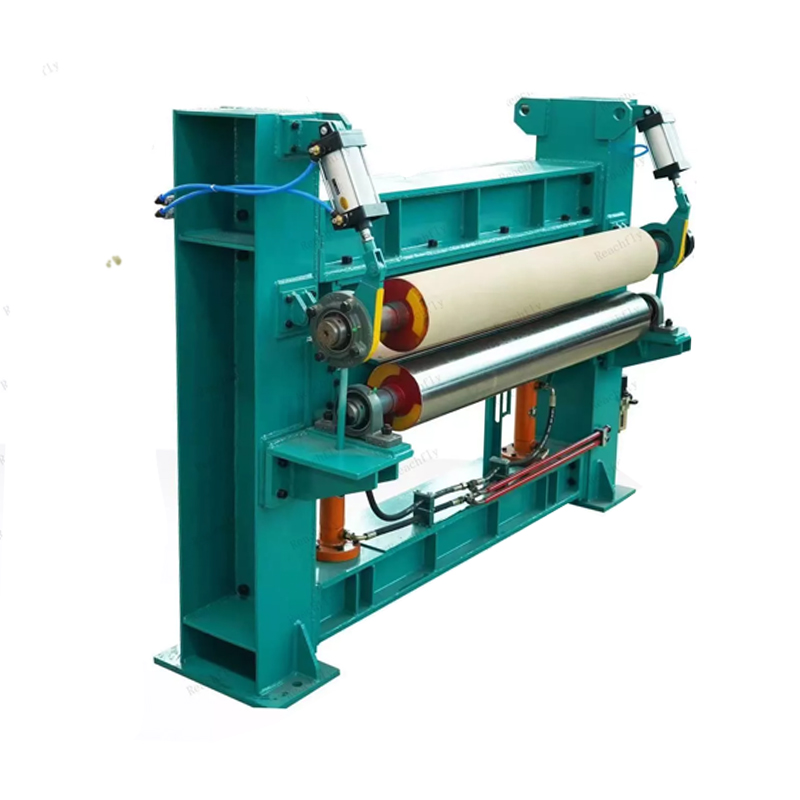

Tensioner/Tension Machine

The tension roller device is a kind of equipment used to implement tension regulation on the continuous production line of strips. The principle is as follows: the strip steel is winded on the tension roller and generates friction on the winding contact, making the outlet tension and inlet tension change according to some rules for this reason, and the tension value is thus changed to implement tension control of the unit.

Tension Roller:

| Diameter | 400-1200mm |

| Press roller | 1-4 press rollers can be selected, diameter of 200-350; driven by air cylinder or hydraulic cylinder |

| Matching devices | servo or dedicated variable-frequency AC motor |

Integrated Cover-coating and Back-coating Machine

1.To guarantee precise coating, the coating machine can coat the steel plate by means of direct coating, reverse coating or whole reverse coating.

2.The front face and the back face of the steel plate can be coated simultaneously, and the heads of the two coating machines for the front face and the back face all have drive equipment.

Two-Roller Precise Coating Machine

1.The precise coating machine is used to implement precise coating on the front face of the passing steel plate by means of direct coating, reverse coating or whole reverse coating.

2.The machine has complete coating machine head and drive device for the front face.

Four-Roller Precise Coating Machine

1.The coating machine implements high-precision coating to the front face of the steel plate by means of reverse coating.

2.Machine head and corresponding drive device.

Uncoiler/Pay Off Reel/Recoiler

Insert the steel roll into the uncoiler mandrel, and meanwhile,expand the mandrel to tension and fix the steel roll. The uncoil mandrel is driven to rotate by variable-frequency AC motor,so as to make the steel plate to maintain the required certain back tension.

The uncoil mandrel is cantilever type and is driven by chains or standard reducer.

The gearbox base is made up by heavy steel plate.

In the mandrel,there are four expandable valves,and the expanding and retracting of the valves are controlled by the revolving hydraulic cylinder at the mandrel tail.

There are four main sliding blocks made of bronze.

The maximum diameter of the expanded mandrel with rubber sleeve is 508mm or 610mm.

Technical parameters:

| Outer diameter of steel roll | Maximum of Φ1500mm |

| Inner diameter of steel roll | Minimum ofΦ508 |

| Width of steel roll | 800-1250mm |

| Maximum steel roll weight | 15-25t |

| Frame and base | Welding low carbon steel |

| Mandrel and pull rod | 40Cr |

| Valve | Cast steel |

| Main sliding block | Casting aluminum brass |

| Retracting size | Diameter of 450mm |

| Expanding size | Diameter of 508mm |

| Rubber sleeve | Thickness of 51mm |

| Expanding and retracting actuator | One rotating hydraulic cylinder |

Sewing Machine

Product introduction:

The machine is dedicated equipment applicable to the head-tail connection of plates and strips in the production line of coating and galvanizing of steel plate,copper plate,aluminum plate,galvanized plate and various plate strips, and is composed of steel-structure body,mold,synchronization system,guiding device and hydraulic system.It can directly lock and sew the strip tail of the coiled plate and the strip head of the next coil without stopping the machine during the operation of unit.The machine has advantages of simple operation,firm sewing,energy-saving and time-saving etc..According to the number of sewing rows,the sewing can be divided into single-row sewing and double-row sewing,and according to the sewing thickness and width,it can be divided into multiple specifications.

Performance:

| Applicable materials | steel plate, copper plate, aluminum plate, galvanized plate and various plate strips. |

| Material thickness | ≤3. 0mm (aluminum plate≤6. 0mm) |

| Material width | ≤1800mm (aluminum plate≤2100mm) |

| Number of sewing rows | 1-2 rows |

| Working pressure | ≤21Mpa |

| Sewing time | ≤10s |

Inquire Now