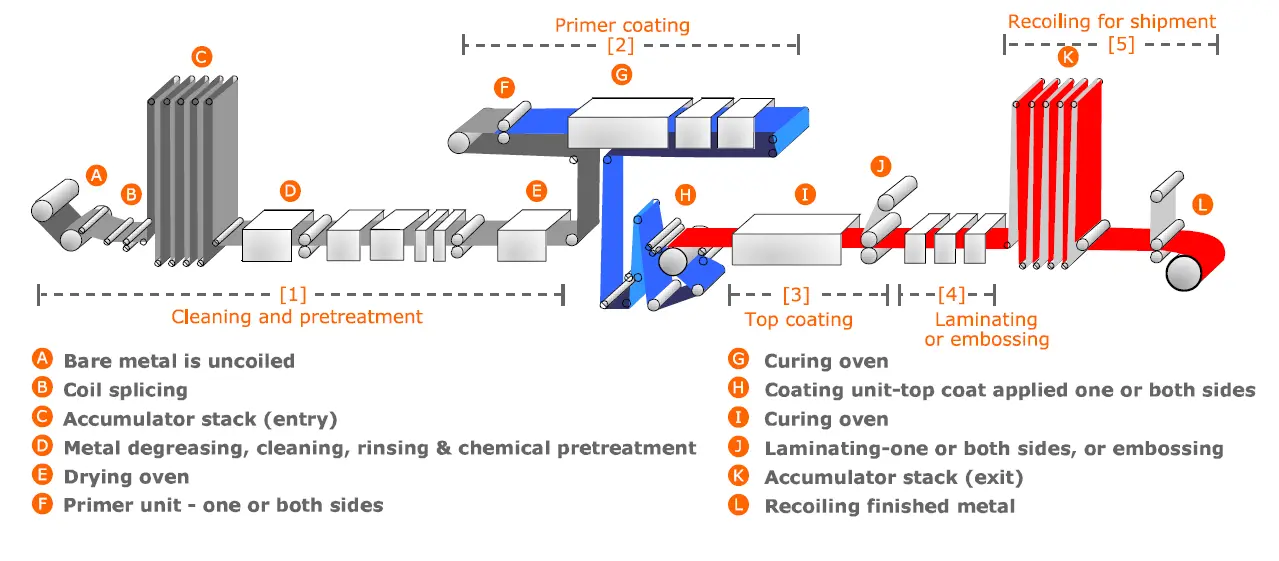

The steel sheet color coating production line is a complete of production equipment for colored steel sheet, and the process is as follows: make the steel coil strips be subject to surface degreasing, parkerising and passivating treatment, then apply multi-layer organic coatings (e.g., coatings of modified resin (SMP), high weather-resistant polyester (HDP), polyvinylidene fluoride (PVDF) etc.) on the strip surface by means of continuous roller coating, next, overprint multi-color patterns, and finally compound to form new functional plates. The production line is composed of equipment of uncoiler, sewing machine, tension machine, storage machine, degreasing and washing unit, roller-coating machine, printing machine, curing furnace, shear, coiler etc.

|  |  |

Technical Paramete

| Material of base plate | Electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate etc. |

| Width of strip steel | 600-1650mm |

| Thickness of strip steel | 0. 12-2.0mm |

| Outer diameter of steel coil | Φ 800-2000mm |

| Process speed | 25-180m/min |

| Thickness of coating | 5-25um for the single-layer dry film on the front face (regulated as required) 5-15um for the single-layer dry film on the back face (regulated as required) |

| Thickness of printing layer | ≤1um (oil ink or polyester) |

| Production capacity | 50, 000-200, 000 t/year |

| Energy type | Electricity, natural gas, liquefied petroleum gas, coal gas, steam, compressed air etc. |

- Line Type: one coating and one baking, two coating and two baking, three coating and three baking.

- Coating Type: epoxy resin, polyurethane, polyester, polypropylene, polyvinyl fluoride, silicon modified polyester

- Chemical Coater: dual-head two-roll type (used in prime coating), three-roll type (used in finish coating front side), two-roll type (used in finish coating back side).

- Catalytic Incineration System: RCO, RTO, DTO

- We also provide Pattern Printing System to produce pattern color coated steel, like the wood grain, brick grain, stone grain, marble grain and so on.

Inquire Now